Every feature of the metallurgical microscope manufacturers distributer is built to provide maximum viewing accuracy and comfort to the user. The coarse and fine focus of the microscope provide control to observe large and small specimens. The metallurgical microscope manufacturers distributer has enhanced illumination technology to give balanced light conditions to highlight color contrasts and fine details. It has also got compatibility with digital imaging software for analysis and documentation to allow researchers to store and compare results efficiently.

In medical and industrial usage, the metallurgical microscope manufacturers distributer finds wide application. Pathologists utilize it to identify cancer cells, microbiologists to characterize bacteria, and botanists to study plant cell morphology. In electronics, the metallurgical microscope manufacturers distributer facilitates defect analysis of printed circuit boards and microchips. Scientists use it to study crystal growth, corrosion, and particle dispersion. The metallurgical microscope manufacturers distributer finds application in forensic science to examine fibers, hair, and residues that are material evidence in cases. Its applications are expanding with advances in optical technology.

The future of the metallurgical microscope manufacturers distributer is influenced by digitalization and smart automation. More efficient imaging sensors will allow the metallurgical microscope manufacturers distributer to identify three-dimensional structures with unprecedented precision. Artificial intelligence will analyze microscopic images, reduce human errors, and optimize research productivity. Wireless communication and cloud connectivity will facilitate collaboration globally with remote monitoring and immediate data exchange. The metallurgical microscope manufacturers distributer will be an entirely networked instrument that closes the gap between laboratory precision and data-driven research outcomes.

The metallurgical microscope manufacturers distributer has the strength of longevity, which is dependent on the right handling and maintenance by cleaning regularly. Clean the eyepieces, objectives, and stage with accepted lens paper after each use. Remove all slides and samples prior to shutdown. The metallurgical microscope manufacturers distributer should be stored in a cool, dry place to avoid corrosion and mold. Check screws and mechanical joints for support at intervals. The electrical components, such as the power supply unit and light source, should be inspected frequently to ensure safe operation.

The metallurgical microscope manufacturers distributer bridges the visible and invisible by rendering small particles and organisms visible. Using a lens system and controlled light, the metallurgical microscope manufacturers distributer enables scientists and students to study samples with utmost precision. It has diverse applications in medicine, biology, electronics, and quality control. Digital and fluorescence forms extend study accuracy, simplifying visualization and data recording in most areas of science.

Q: What distinguishes a digital microscope from a traditional one? A: A digital microscope integrates cameras and imaging software, enabling users to view, capture, and analyze images directly on a computer or monitor. Q: How can vibration affect a microscope? A: Vibration can cause image blur or misalignment, so the microscope should always be placed on a stable, vibration-free surface. Q: What safety measures should be taken when using a microscope? A: Avoid touching optical parts with fingers, use slides carefully, and ensure electrical components are safely connected before operation. Q: Why is immersion oil used in some microscopes? A: Immersion oil increases the refractive index between the lens and specimen, improving resolution and brightness at higher magnifications. Q: How can you prevent mold growth in a microscope? A: Store the microscope in a low-humidity environment and use desiccants or dehumidifiers to keep optical components dry and mold-free.

We’ve been using this mri machine for several months, and the image clarity is excellent. It’s reliable and easy for our team to operate.

The hospital bed is well-designed and very practical. Patients find it comfortable, and nurses appreciate how simple it is to operate.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

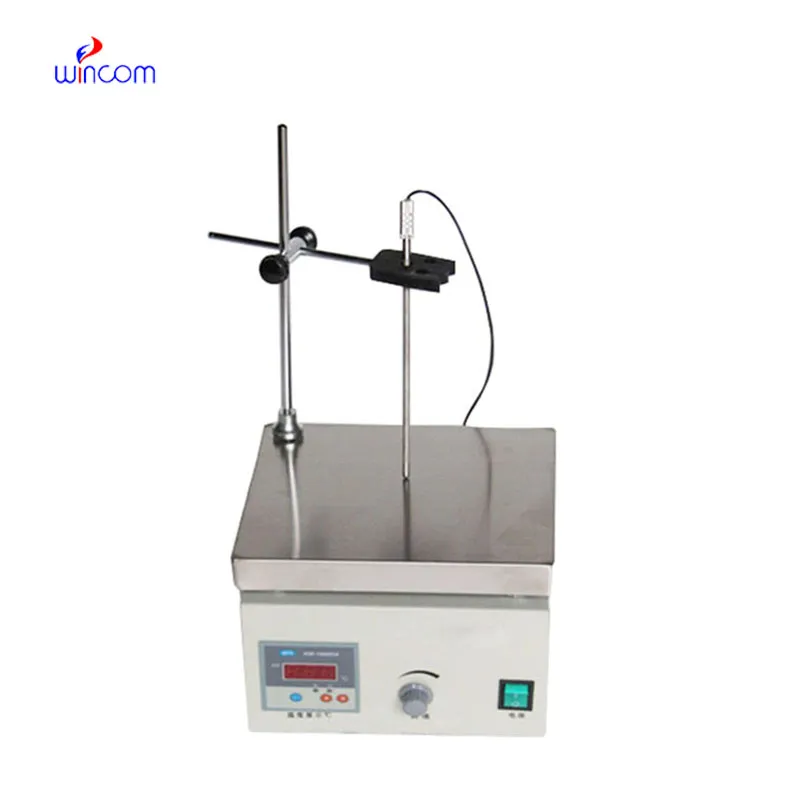

Hello, I’m interested in your water bath for laboratory applications. Can you confirm the temperat...

We are planning to upgrade our imaging department and would like more information on your mri machin...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China