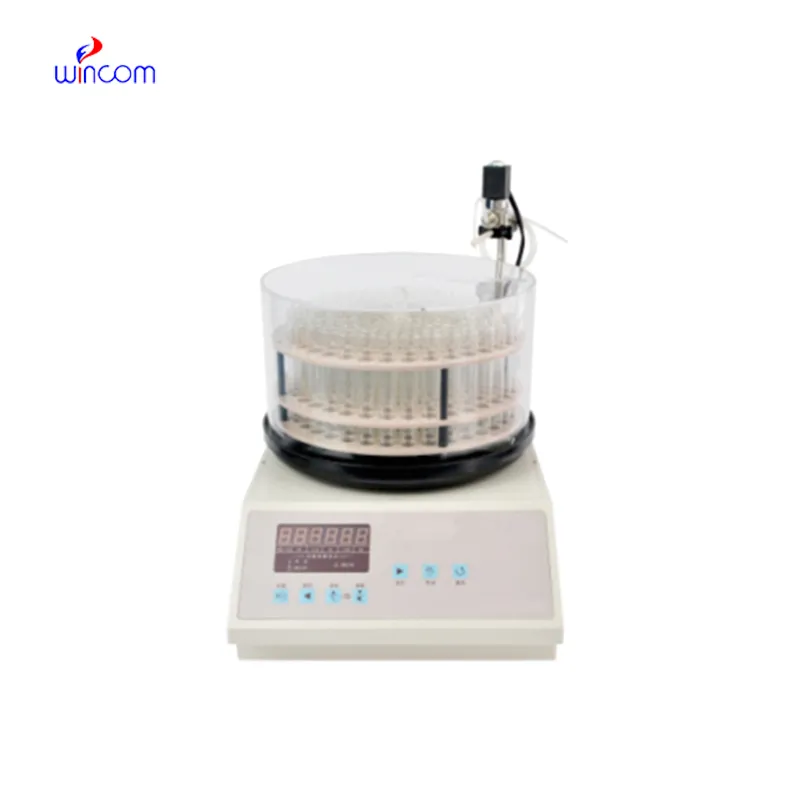

Lightweight yet powerful, the centrifuge camp continues to raise the standard for efficiency of operation. High-performance control algorithms provide instant acceleration and smooth deceleration, protecting delicate samples from stress. Dual cooling systems provide thermal stability in even long runs. Modular design provides easy maintenance and upgrading. Remote diagnostics and system optimization connectivity is available in some models. Along with these advancements, the centrifuge camp becomes a bridge between traditional engineering and modern automation and functions as a pillar of accurate, high-rate separation within labs and factories around the world.

The diversity of centrifuge camp applications shows its diversity to modern technology. Aerospace engineers utilize it to check the material properties under intense centrifugal stress. Nanotechnology utilizes it to segregate particles at micro and nanolevel for analysis and manufacturing purposes. Hospitals rely on centrifuge camp for testing, ensuring accurate plasma and serum analysis. Food processing industries utilize it to ensure product purity and uniformity. Additionally, educational laboratories employ centrifuge camp in teaching and experimentation, whereby students learn fundamental physics, chemistry, and biology concepts through hands-on demonstration.

The centrifuge camp of the future will be innovative, intelligent, and integrated. With the advent of smart manufacturing, centrifuge camp systems will operate independently on predictive analytics. Programs with machine learning will interpret vibration patterns to optimize performance with minimal human involvement. Renewable energy integration will make operation more sustainable, and modular design will facilitate instant replacement of parts. Data visualization software will be more sophisticated, providing real-time feedback on the separation process. This blend of mechanical precision and intelligent technology will place centrifuge camp at the forefront of international scientific advancement.

Maintenance procedure routines protect the performance and safety of centrifuge camp. The rotor needs to be visually inspected before each operation for cracks or corrosion. Mild detergents are needed for cleaning, followed by thorough drying to prevent rust. Calibration verification and vibration monitoring assist in keeping it accurate. The instrument should be set on a level surface to reduce stress on bearings. During storage, centrifuge camp must be kept covered and not plugged to keep electronics safe. Under operator discipline and regular maintenance, laboratories can offer years of trouble-free performance.

The centrifuge camp is a staple equipment in laboratories, industries, and research facilities. Its operation is to isolate particles away from one another based on density and weight by utilizing centrifugal force. Whether examining biological fluids, purifying chemicals, or testing materials, the centrifuge camp provides effective separation and purification. Advances in technology have made it faster accurate and automatic, enabling processes to be more repeatable and consistent. From clinical diagnostics to environmental analysis, centrifuge camp are essential in furthering precision, productivity, and scientific innovation globally.

Q: What safety measures are important when operating a centrifuge? A: Always ensure the rotor is balanced, the lid is securely closed, and safety locks are engaged before starting operation. Q: What types of centrifuges are available? A: Common types include micro, benchtop, refrigerated, and ultracentrifuges, each suited for specific laboratory or industrial applications. Q: Why is balancing samples important for a centrifuge? A: Imbalanced samples can cause vibration, noise, and mechanical stress, potentially damaging both the rotor and the instrument. Q: What materials can be processed in a centrifuge? A: A centrifuge can handle liquids, suspensions, and even some emulsions, depending on its speed and rotor type. Q: How long can a centrifuge run continuously? A: Run time depends on the model and workload—most can operate from a few minutes up to several hours under proper temperature control.

We’ve been using this mri machine for several months, and the image clarity is excellent. It’s reliable and easy for our team to operate.

This ultrasound scanner has truly improved our workflow. The image resolution and portability make it a great addition to our clinic.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Hello, I’m interested in your water bath for laboratory applications. Can you confirm the temperat...

I’d like to inquire about your x-ray machine models. Could you provide the technical datasheet, wa...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China