The operation of an ahlstar centrifugal pump largely relies on its rotor design, accuracy in balancing, and operating speed. Modern models typically come with programmable interfaces that allow users to control acceleration rates, temperature, and run times with great accuracy. Some advanced ahlstar centrifugal pump incorporate vibration sensing and auto-imbalances for stabilizing high-speed rotation. Additionally, the use of light but strong materials like carbon fiber enhances safety and energy efficiency. This marriage of engineering ingenuity and electronic control combines the ahlstar centrifugal pump into a reliable partner for research and production environments.

The use of ahlstar centrifugal pump traverses a number of scientific disciplines. In the manufacture of pharmaceuticals, it cleanses chemical compounds and removes residual unwanted matter. Biochemists employ ahlstar centrifugal pump in fractionating cells and isolating organelles for subsequent studies. Drink producers utilize it to filter fluids and stabilize their products. The oil and gas industries utilize ahlstar centrifugal pump to enhance fuel refining and clean products. {Keywords} can also be utilized in environmental analysis, aiding in the detection of pollutants in water and air samples. They are highly accurate and flexible, thus being a fundamental tool within laboratories and the manufacturing industry.

The ahlstar centrifugal pump technology future lies in automation, digital control, and green engineering integration. Future models will include AI algorithms for speed, balance, and separation efficiency automatic optimization. Energy-efficient motors and recycled materials will reduce environmental impact, following international sustainability goals. Cloud connectivity will allow for remote monitoring and predictive maintenance, with less downtime. In laboratories, ahlstar centrifugal pump will be completely compatible with smart data systems for real-time reporting and process validation. These innovations promise greater accuracy, reliability, and versatility for research and industrial use.

Proper care routines prolong the life of ahlstar centrifugal pump significantly. Operators should inspect the rotor for corrosion or scratches after each use and clean with non-abrasive substances. The lid and chamber should be free from residue to prevent contaminations. Frequent lubrication of mechanical interfaces ensures effortless movement. Temperature and humidity control in the storage room protect internal parts against damage. A maintenance record helps track service time and early wear detection. Ongoing maintenance of these factors allows ahlstar centrifugal pump to perform reliably for decades.

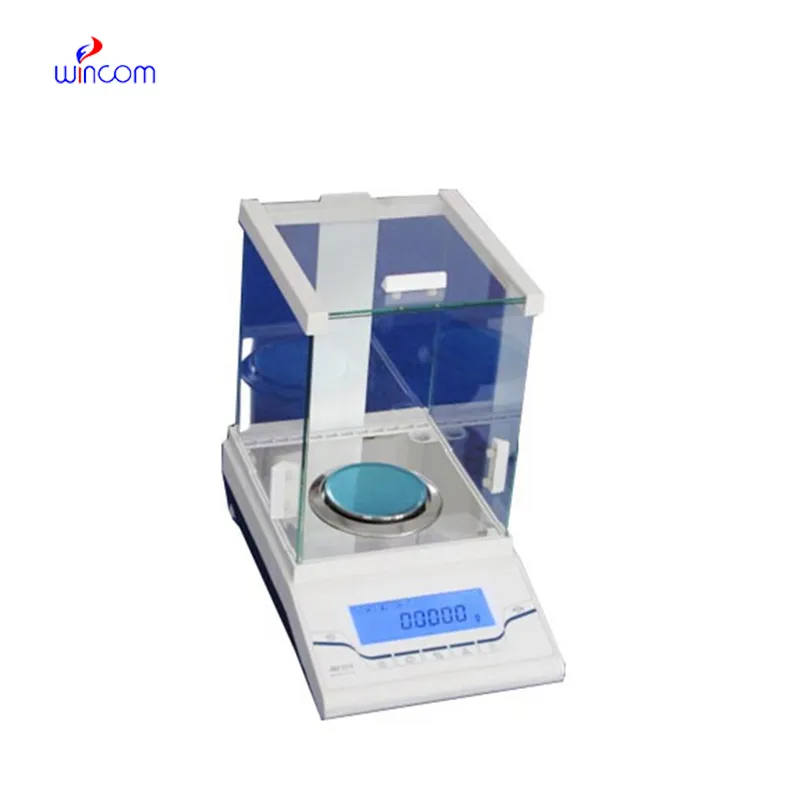

ahlstar centrifugal pump is a piece of mechanical equipment that separates simple mixtures into differentiated parts by utilizing quick spinning. It functions by employing centrifugal force, which expels heavier elements and brings lighter elements closer towards the axis. This principle makes crucial work possible in microbiology, pharmaceuticals, and materials science. High-speed models can achieve exceptional separation accuracy in mere minutes. Modern ahlstar centrifugal pump feature digital interfaces, temperature control, and advanced safety locks to ensure operation. They are so fast and versatile that they are a must-have asset for any laboratory or manufacturing plant.

Q: How is a centrifuge different from a mixer or shaker? A: Unlike mixers or shakers that blend materials, a centrifuge separates components based on density through high-speed rotation. Q: What power requirements does a centrifuge need? A: Most benchtop centrifuges use standard AC power, while industrial units may require higher voltage for greater speed and capacity. Q: Can a centrifuge be used in pharmaceutical production? A: Yes, centrifuge equipment is widely used to purify chemical compounds and biological materials during drug manufacturing processes. Q: How do I prevent vibration during operation? A: Ensure all tubes are evenly loaded, rotors are clean, and the machine is placed on a stable, level surface. Q: What is the lifespan of a centrifuge? A: With regular maintenance and proper usage, a centrifuge can last for many years while maintaining consistent performance.

We’ve used this centrifuge for several months now, and it has performed consistently well. The speed control and balance are excellent.

This ultrasound scanner has truly improved our workflow. The image resolution and portability make it a great addition to our clinic.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

I’d like to inquire about your x-ray machine models. Could you provide the technical datasheet, wa...

We are planning to upgrade our imaging department and would like more information on your mri machin...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China